We are supporting the data revolution by driving optical fiber processing from cottage industry to advanced mass production over the past 25 years.

Global growth in the demand to rapidly move ever-increasing amounts of data is fueling the development of the optical communications network. The transition from copper to optical fiber for data transmission is an inevitable trend but has required a revolution in manufacturing methods to provide the processes and tools to terminate the optical fibers and the other optical components required.

As just one example, there are over 4bn USB devices on the planet (Source: In-Sat, 2014). As these transition to USB 4, which uses optical fibers for the data transmission, there will be a need for a similar number of optical cables to be produced. This is in addition to the >2bn cables needed for datacenters (Source: Ethernet Alliance 2013, CIR 2014), giving a requirement of order 10bn cables.

Conventional fiber-processing techniques involve mechanical cleaving and polishing, which are slow, multi-step, have yield issues and cannot achieve the volumes or price points that consumer applications will demand. The traditional processes are also problematic to automate, leading to labor-intensive manufacturing in low cost-base locations.

The OpTek team developed the first commercially available technology for laser processing of optical fiber during the 1990s and, since this time, has gone on to develop a diverse range of tools for use in the production of optical fiber cables, assemblies, and optical components. These include:

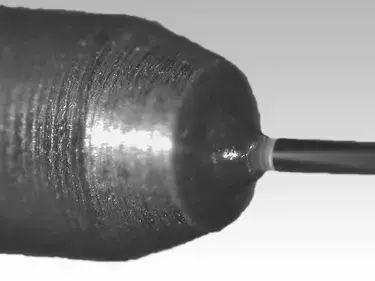

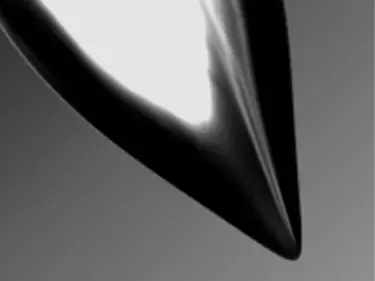

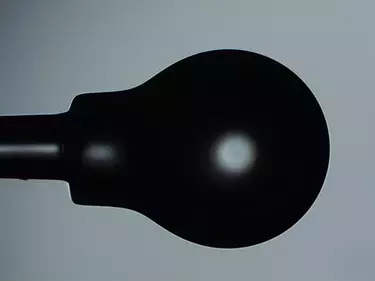

- Direct lensing of optical fiber for interfacing with active devices and waveguides. The laser lensing process was originally developed to produce large volumes of high coupling efficiency, low cost, fiber tails for pump lasers.

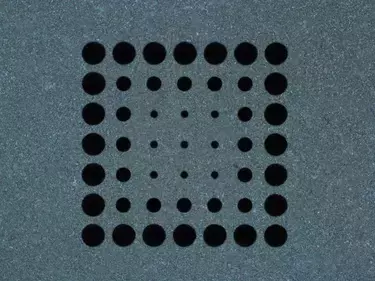

- Optical quality cleaving or fiber for low loss termination/connections for a range of applications. Laser cleaving provides a superior optical quality to mechanically terminated fiber, with process times typically in the fractions of a second. Laser cleaving can create flat faces, at angles from 0° to greater than 45°, on single or multi-fiber assemblies.

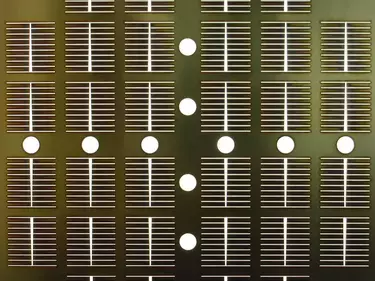

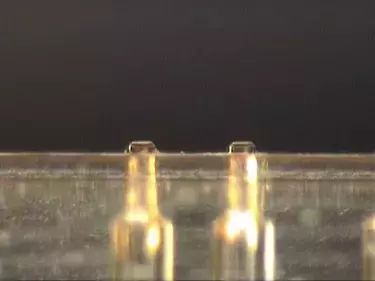

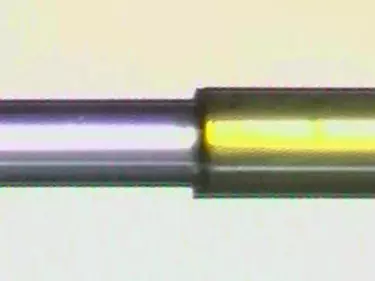

- Precision cutting of optical fiber and epoxy in standard optical fiber connectors. The fiber “stinger” can be cut exceptionally close the ferrule, reducing post polishing to one or two steps, with exceptional first-pass yields.

- We have an installed base of hundreds of machines worldwide, terminating fiber for optical comms

- OpTek machines are in production, providing the optical fiber termination for optical HDMI cables.

- OpTek machines are approved for a range of next-generation optical connectors.

Need our help? Fill out our form to ask our OpTek experts.