Laser micromachining offers unique advantages for materials processing in an ever-increasing range of applications.

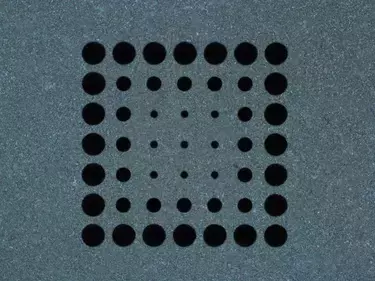

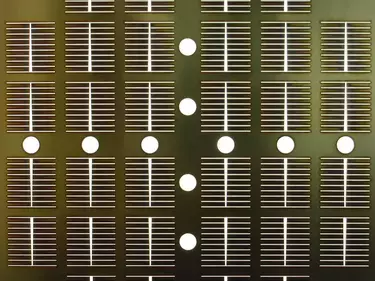

From micro holes with diameters down to a few microns and sub-micron tolerances to laser scribes a few 10’s microns wide and km’s long, laser processing and micro-machining provides a highly versatile engineering solution.

A wide range of laser technology is available, allowing the laser process to be tuned to the particular material and feature type required, with a high degree of control over the laser/material interaction. The delivery of the laser energy can be controlled to such an extent that lasers can be applied to highly thermal processes such as heat treatment and welding through to “cold” vaporization of materials for precision micro-hole drilling. Moreover, the properties of the laser can be chosen to allow selective removal of one material from another and the beam can be scanned rapidly to create larger features for laser cutting, laser drilling, laser milling, laser scribing, laser dicing, laser marking and 3D laser micro-milling.

The following pages illustrate this highly diverse, precision micro-machining capability, however, to discuss your specific requirements please do contact us directly.

Need our help? Fill out our form to ask our OpTek experts.