Solving the most challenging problems with unmatched expertise and production capability.

Recent years have seen a growing number of companies offering basic laser micromachining equipment and services. But for most applications, basic isn’t good enough. When your application involves unconventional materials, innovative processes, extreme precision, massive production volumes, global delivery, and extreme deadlines, that’s when OpTek shines. Of course, we can also handle your basic needs—with exceptional responsiveness and service.

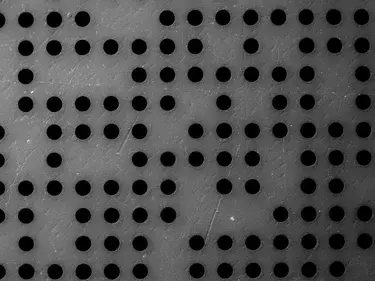

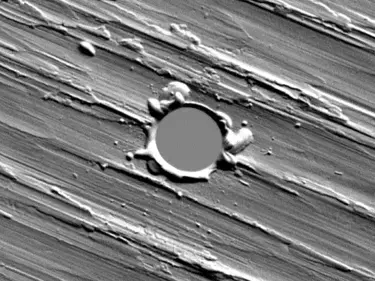

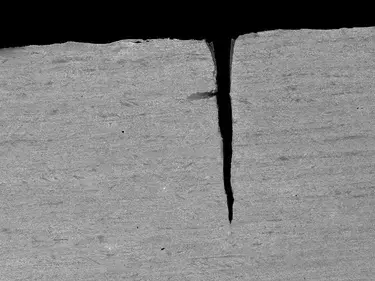

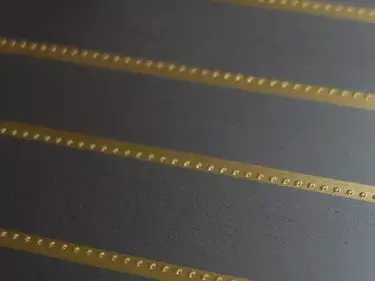

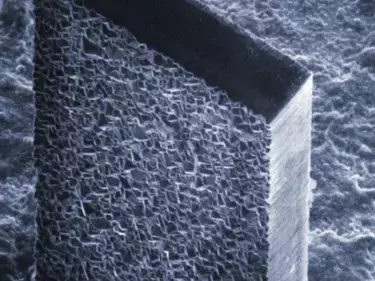

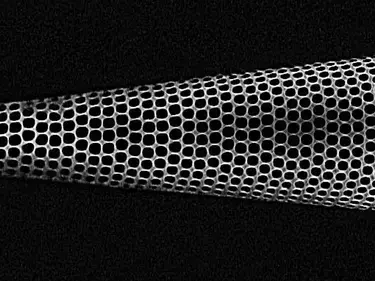

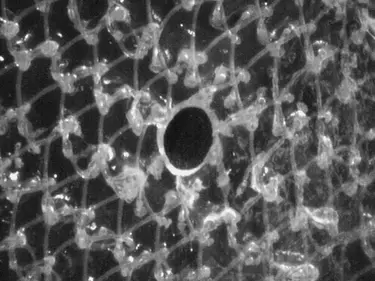

OpTek has proven experience dating to the dawn of laser micromachining technology. We have the expertise for micromachining virtually any feature into any material for any requirement—all the way from laser-marking chocolate to fabricating microfiltration systems for the most advanced medical devices. We know how to analyze your application design and apply the optimum process to achieve it, whether that means getting unprecedented results using conventional laser technology or applying state-of-the-art technologies such as ultra-short-pulse lasers.

Whether you need a part, a subsystem, a complete machine—or prefer to let us do your laser micromachining on a contract manufacturing basis—the applications you see here are only a sample of what we can do. Contact us to discuss your specific needs.

Need our help? Fill out our form to ask our OpTek experts.