Making new applications possible with unique laser technologies that do what traditional fabrication techniques can’t.

Explore new engineering possibilities. OpTek has an extensive and innovative laser processing toolbox that enables applications that would be difficult or impossible to achieve with conventional optical fiber processing techniques.

Traditional abrasive and tool-based cleaving, lensing, and stripping methods are limited in the geometries they can achieve; are prone to abrasion, chipping, and other imperfections that can only be discovered in a separate inspection step; and can cause significant yield loss. OpTek’s laser-based methods solve all these issues—enabling simultaneous processing and inspection of precise design features for almost any specification, with virtually 100% first-pass yield.

Examples of our laser processing toolbox for fiber processing applications include:

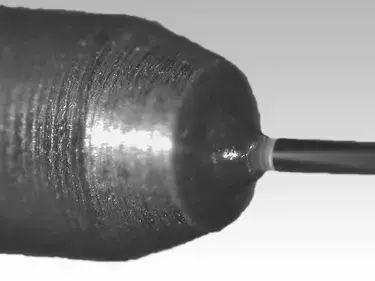

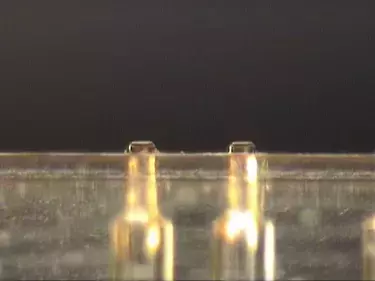

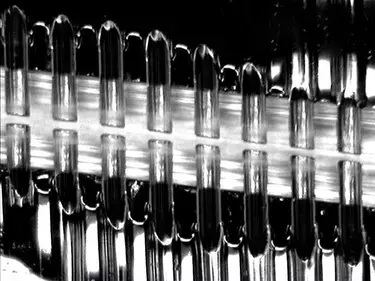

- Laser cleaving, including cylindrical, tapered, conical, angled and flat. These forms are used to provide high coupling efficiency between optical fibers and the laser source or receiver. Applications include telecommunications, data communications, fiber lasers, biomedical devices, energy exploration and production, gyroscopes, and a range of sensing applications.

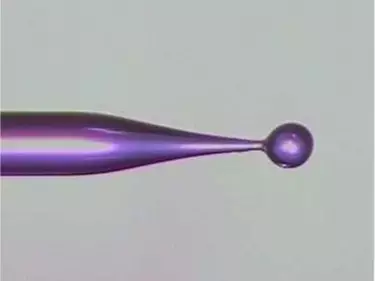

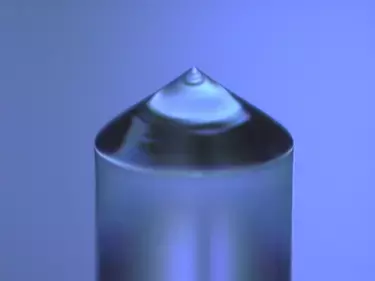

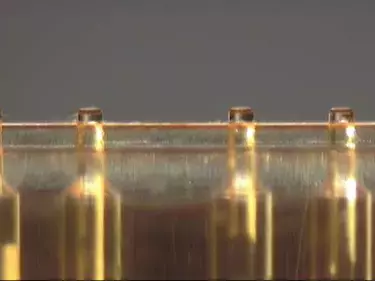

- Laser lensing, including conical, wedge, and biconic. High-performance lens forms are created directly on the end of optical fibers, with the unique ability to cleave and lens fibers already assembled into fixtures or ferrules. Applications include radial light emission for medical and dental procedures; probes for biomedical spectroscopy; light focusing for high-efficiency coupling with waveguides, source and detector coupling in telecom and military applications; and many others.

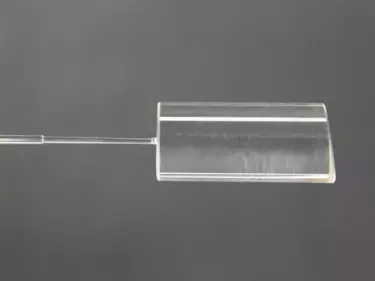

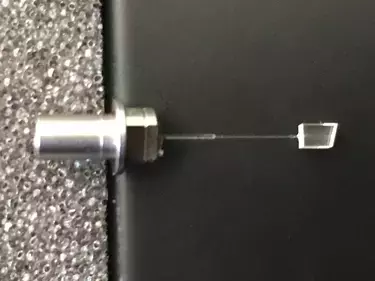

- End capping. This reduces power densities to increase the damage threshold of the fiber component. It can also be used to modify beam shape emission through numerical aperture or mode field diameter manipulation or to modify beam direction and properties. Applications include high-energy beam delivery in defense, medicine, and a variety of sensing systems.

- Laser stripping. Acrylate, polyimide, and other buffers can be removed through a non-contact process, with precise dimensional control for both end-stripping and window-stripping. Applications include medicine, defense, aerospace, undersea, and others that require ultra-high reliability.

- Advanced fiber assemblies: OpTek can also build complete, turnkey fiber optic assemblies for any application requirement, including terminators and connectors, feed-through tubes, solders, fiber Bragg gratings, and harsh-environment probes. With a single source for complete fiber assemblies, you can simplify your supply chain and count on reliable delivery and performance.

Whether you contract the work to OpTek or perform it yourself using OpTek technology, we help make your innovative new designs manufacturable. Let’s talk about your ideas and how to bring them to reality.

Need our help? Fill out our form to ask our OpTek experts.